|

FIBERGLASS NEEDLE MAT

|

||||||||||

|

|

||||||||||

|

|

||||||||||

|

||||||||||

|

|

C Method of Manufacture:

This product uses E type glassfiber roving as our raw materials while each strand is chopped into a 2~3 inch fraction via the fiber cutting machine and further decomposed into extreme tiny blanket shape through the cotton carding engine. Subsequently, our needled fabrics are ceaselessly sewn by thousands of needles. |

|

||||||||

|

|

D Virtues:

The product adopts inorganic E type glassfiber along with the main components of silicone Al O and CaO. Also, it is characterized by heat-resistance, tensile strength, tenacity fireproofing, anti-erosion, and good electrical insulation. The adoption of extreme tiny E type glass fibres followed by particular needling leads to numerous thin holes with the glassfibre blanket so as to provide heat-insulation and sound-absorbency. |

|||||||||

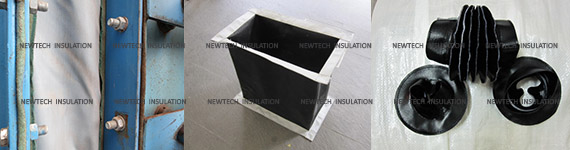

With excellent thermal insulation and easy installation, the flexible removable, detachable and reusable insulation systems are to provide the user with a cost efficient means to insulate frequently maintained equipment in the plant. Our removable insulation covers can be used for a wide variety of high temperature; low temperature; and sound suppression applications in energy conservation(energy-savings), personnel protection, freeze protection and noise protection, also offer increased efficiency, lower engine compartment/ room temperature, and protection to electrical components/ personnel. They can save you time and expense wherever insulated equipment needs access for operation, inspection or maintenance.

The removable thermal insulation jackets (covers) can be fabricated many different ways depending on the materials used, the application and the customers' requirements. Usually, The removable thermal insulation jacket consists of surface layer, insulation layer, and liner and/or anti-abrasion layer inside. Weather barrier will be used as its outside surface when it is exposed to the weather. Seams are sewn with high temperature threads, usually with Kevlar TM, PTFE coated glass fiber or stainless steel thread to suit application. We can also offer specialized threads including Quartz and continuous filament ceramic for resistance to extremes of temperature.

All insulation covers are secured with:

a). Hooks and back plates (brass, nickel or stainless steel).

b). Velcro TM hook and loop strip.

C). Laces and Eyelets

d). D Buckles and Belts.

e). Other securement is also available upon request.

The service temperature depend upon the different materials used, the highest temperature is 1200(C).

Typical applications are including:

· Steam turbines, gas turbines (as turbine blankets) and compressors

· Exhaust systems of engines, Generators

· Heat exchangers, Man ways

· Extruders, Strainers, Filters

· Pumps, Valves & Flanges

· Expansion Joints, Flex Hose

· Tank Covers

· Feed water heater heads

|

||

|

||